Conversion of Proxxon MF 70 micro

miller to a 3-axial CNC

Description

Proxxon

MF70 micro miller can be easily converted to

a small, but precise 3-axial CNC machine using stepper motors and gears from three

old printers HP LaserJet 1018 or 1020 (probably also 1010, 1012, 1015 and 1022,

but not confirmed), three stepper motor driver boards X-NUCLEO-IHM03A1 (3 ea)

with powerSTEP01 drivers of STMicroelectronics and one

development board with LCD touch panel DISCO-F746NG with ARM Cortex M7 microcontroller

STM32F746NG of STMicroelectronics.

This set of four development

boards together with a new electronic shield containing a few cheap electronic

modules (RTCC, Wifi, Bluetooth, DC/DC step-down converter) will provide the following

control functions:

• Manual

control of CNC axes using LCD touch panel of DISCO-F746NG

• Automatic

execution of g-code from an integrated SD card of DISCO-F746NG

• Loading

g-code to the SD card remotely via USB, Ethernet, Wi-Fi or Bluetooth from

computers or mobile devices (mobile phones, tablets).

• Connecting

external sensors: end-stops on all axes, digital thermometers on all motors,

thermo-camera MLX-90621 and a camera STM32F4DIS-CAM for visual control of

machined parts.

• Data

and video transfer from the CNC back to a computer or a mobile device for

on-line diagnostics.

This simple and cheap CNC can be used for

making printed circuit boards (PCB), engraving and

milling wood, plastics or soft metals, especially in

school labs and hobby clubs. The effective working area of the final CNC is

approx. 130/43/74 mm X/Y/Z, micro-step resolution is 82 nanometers in all axes.

The developed electronic hardware and software is not limited to Proxxon MF70

only, but it can also be used for much more powerful types of 3-axial CNC

machines, with stepper motors up to 50 V / 10 A power limit each.

A short video of the first prototype of

the CNC with an example of a simple PCB milling and drilling can be seen here

for illustration:

Video

The following manual describes an

improved version of the first prototype and contains:

1.

Procedure for dismantling old HP LaserJet

printers.

2. Documentation

of the electronic hardware, including Eagle CAD files and the bill of materials

for the electronic shield with power supply, end-stop connectors, real-time

clock and calendar module (RTCC), digital thermometers connectors, I2C output

for thermo-camera and UART output for Wi-Fi and Bluetooth modules.

3. Documentation

of the mechanical hardware, including FreeCAD, STEP and STL files for their 3D

printing.

4. Procedure

for the assembly of the electrical and mechanical parts to the CNC setup (work

in progress).

5. Program

for DISCO-F746NG for manual control and for automatic g-code loading from a SD

card (work in progress).

6. Video

signal acquisition from a camera and a thermos-camera (work in progress).

7. Programs

for a PC and mobile devices for CNC remote control via USB, Ethernet, Wifi

and/or Bluetooth (work in progress).

Dismantling HP LaserJet printers

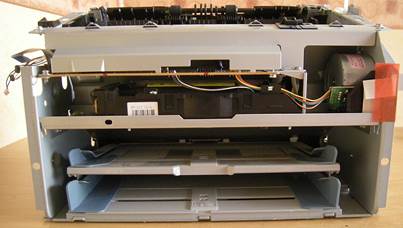

The

described conversion of the Proxxon MF70 miller to a CNC machine requires

stepper motors Mitsumi

M49SP-2K and specific gears

from three HP LaserJet printers. These motors and gears are for sure used in HP

LaserJet 1018 and 1020 series, probably (but not confirmed) also in 1010, 1012,

1015 and 1022 series. You will need to get three pieces of these old printers,

the best for free from the electronic waste scrap yards, or eventually from

eBay. The photos below show disassembly of HP LaserJet 1020:

1.

Unscrew all screws and remove all plastic

parts from the printer. Pass the toner cartridge to the toner recycling

facility.

c

c

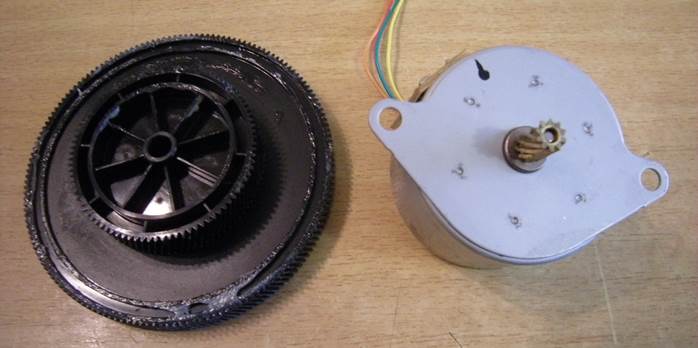

2. There

is a set of gears under a steel plate with a green electronic board on the

right side of the printer. You will need just the largest gear pointed to by

the red arrow bellow:

3. The

stepper motor is screwed to the other side of the metal plate. Unscrew it and

cut its leading wires at the powering board leaving as long wires as possible

with the connector at the motor.

4. The

largest gear and the motor is all you will need from the printers for the CNC

machine.

5. You

will however get much more materials from the printers, which you can use in

other electronic or robotic projects. For example: lots of sheet metal, plastic

plates, linear and rotary gears, steel rollers, screws and springs, four

optical gates (switches/interrupters), electromagnet, and the best of all – the

laser unit for which use you can find recipes elsewhere (but work with care!)

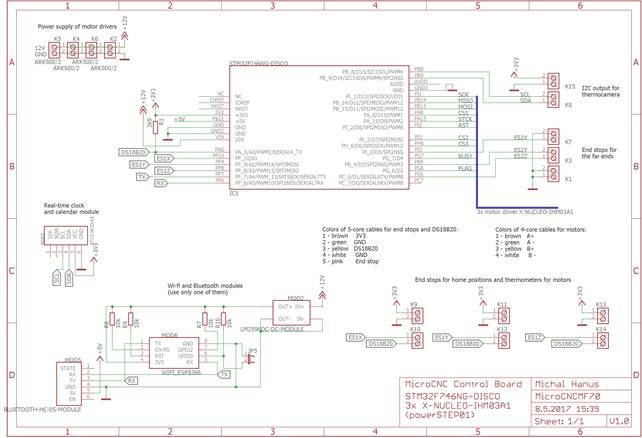

Documentation

of the electronic hardware

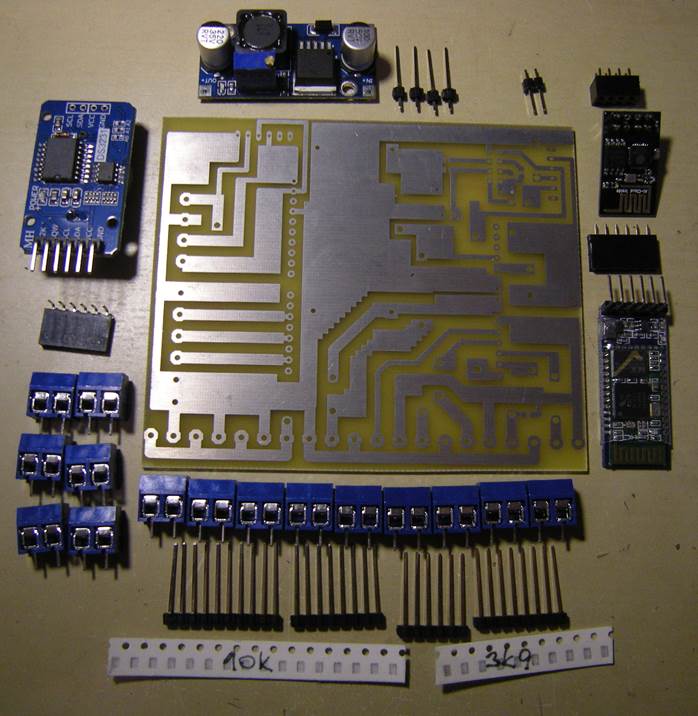

You will need these parts for electronic

hardware of the CNC machine:

-

DISCO-F746NG - a development board

with STM32F746NG - ARM Cortex M7 series microcontroller, 4,3´´ LCD touch panel,

ethernet and USB connectors, camera connector, SD card slot, external SDRAM and

Flash memory chips, audio inputs and outputs, as the main control board and

user interface.

-

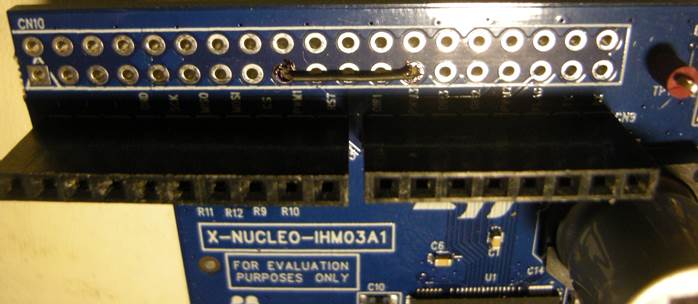

3 ea X-NUCLEO-IHM03A1 – development

boards with powerSTEP01 stepper motor driver, probably the most modern and

powerful stepper motor driver available (50VDC/10A), with SPI communication for

commands and diagnostics, up to 128 microsteps, 22-bit internal microstep

counter, voltage or current regulation, running with user-defined speed

profiles to selected positions etc.

-

Real-time

clock and calendar module (RTCC) ZS-042 with

DS3231 chip and AT24C32 EEPROM, communicating with the microcontroller of the

main control board via I2C and keeping the real time and date for the control

software (optional).

-

Wifi

module ESP8266 for wireless communication with the

CNC (optional).

-

Bluetooth

module HC-05 for an alternative wireless

communication with the CNC (optional). Please note that you can use either Wifi

or Bluetooth for wireless communication, not both of them simultaneously.

-

DC/DC

step-down module with LM2596 for effective 3V3

powering of the power-hungry WiFi module (avoiding overloading LDO of the main

control board).

-

3

ea DS18B20 digital thermometers for control of

the motor overheating.

-

MLX90621

thermocamera sensor for detection of the

tool overheating (optional).

-

STM32F4DIS-CAM

camera board for remote visual control of the

CNC operation (optional).

-

Stabilized power supply 12 VDC, at least

4 A output (e.g. ATX old casdesktop computer power supplies or LED strips power

supplies).

-

PCB board, single layer, approx. 100 x 85

mm.

-

15 ea 2-pin terminal connectors, pitch 5

mm (e.g. TB-5.0-P-2P)

-

SMD 0805 resistors 3k9 (1 ea) and 10k (4

ea)

-

Microswitches of any suitable and

miniature types as end stops (6 ea)

-

4-pin

microphone connectors for connecting motors

and thermocamera (4 ea)

-

5-pin

microphone connectors for connecting end

stops and digital thermometers (4 ea)

-

4-core shielded cable 4x0.25 mm2

for connecting motors and thermocamera (at least 5 meters)

-

5-core shielded cable 5x0.25 mm2

for end stops and digital thermometers (at least 5 meters)

-

PG9

plastic bushings for fixing cables entering control panel case (7 ea).

-

Auxiliary connectors: jumper (1 ea),

18-mm-long pins (32 ea), pin connectors with 2.54-mm-pitch (1 ea angled, 1 ea

straight), 4x2 connector with 2.54-mm-pitch (1 ea), power connector 2.5/5.5 mm

– see the photo with parts below.

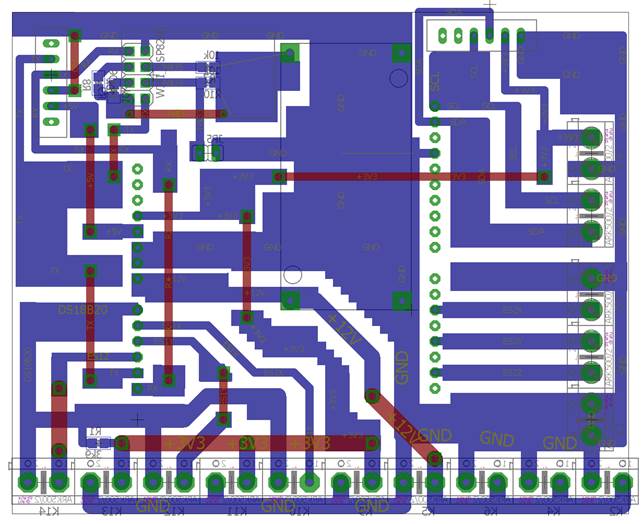

Make printed circuit board of the

electronic shield according to the following schemes (the Eagle CAD files are

attached below):

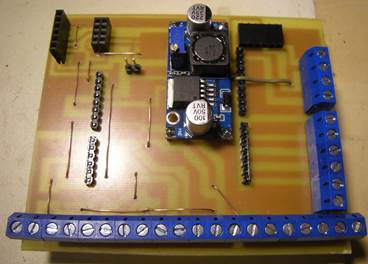

Assemble the PCBs with components as

shown in the schemes and the photos below.

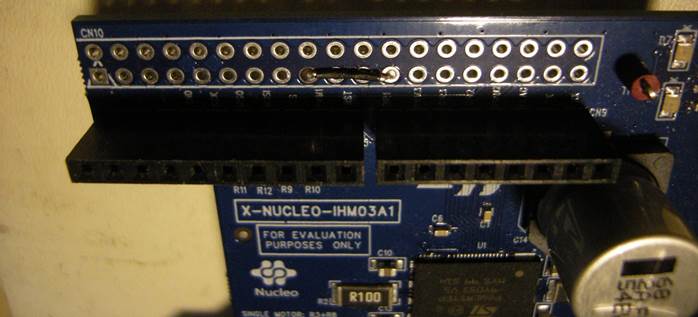

Take the three X-NUCLEO-IHM03A1 motor

driver boards and solder wires for chip select pins (CS) between these ports on

the board as follows:

Driver board No. 1: no connection (CS1

pin stays as ported on the original board)

Driver board No. 2: connect 9th

port of CN10 inner column with the 12th port at the same column and

bend the 8th pin (CS1) below the board to the right angle, making

CS2 pin connection.

Driver board No. 3: connect 9th

port of CN10 inner column with the 13th port at the same column and

bend the 8th pin (CS1) below the board to the right angle, making

CS3 pin connection.

The electronic hardware is now ready for the

final assembly.

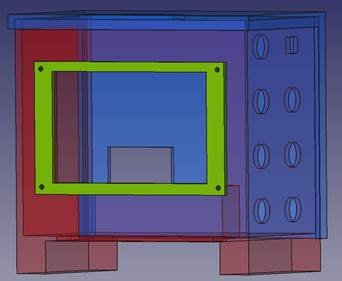

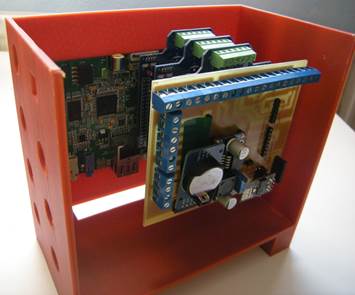

Documentation

of the mechanical hardware

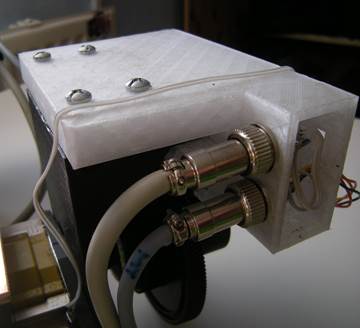

This CNC conversion kit requires to

3D-print a few pieces of mechanical adapters for the Proxxon MF70 miller and a

case for the Control Panel. All these mechanical parts are designed in FreeCAD

- an open-source parametric modeler and are exported to STEP format for

compatibility with other CAD software, as well as to STL format for 3D

printing. All the design files are attached below.

As for 3D printing, the Control Panel

case can be printed from normal PLA with a low infill (20 %), but the parts to

be mounted on the CNC machine are recommended to be printed from PETG with a

high infill (50 %) to assure both good flexibility of PETG compensating for

irregularities of fixtures, and high mechanical strength of these fixtures.

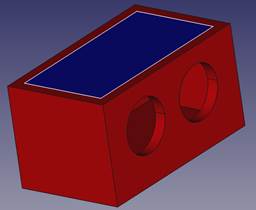

1. Control

Panel case consists of 3 parts - front panel, protection frame around the LCD

and the back panel.

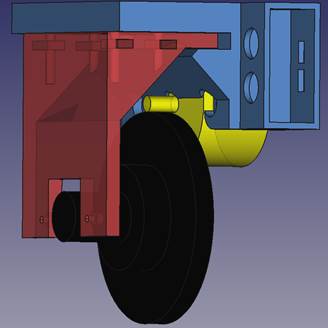

2. Fixtures

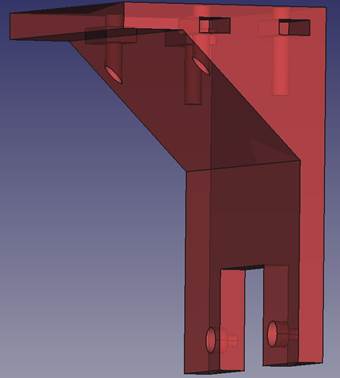

on the CNC axes consist of the following parts:

-

Axis holder (red)

-

Axis handle (black) holding the gear.

-

Motor holder (blue) for the stepper motor

(yellow)

-

Connector lid

Axis holder is screwed to the Proxxon

MF70 axes and holds the motor holder – it is designed specifically for the

respective axis.

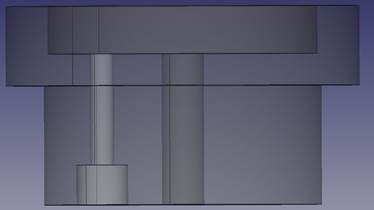

Axis handle

adapter (to be fixed to the manual handles of the Proxxon MF70 axes and holds

the gear) should be printed in 3 pieces to cover all the axes.

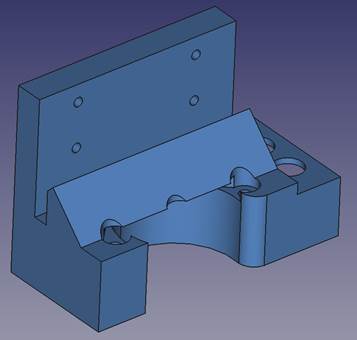

Motor holders are designed specifically

for each of the three axes and differ in size and position of the connector

boxes.

One more

connector box with a lid shall be printed separately to connect the far-end

stops and thermo-camera cables. Three more separate lids for the connector

boxes at the motor holders shall be printed as well.

The other chapters on final assembly and

software are still in progress, so if interested in this project, please come

back soon for more details or contact me at mikehanus@protonmail.com.

Files